The role of HPMC in wet mortar

Wet mix mortar: Mixed mortar is a kind of cement, fine aggregate, admixture and water, and according to the properties of the various components, in a certain proportion, after measurement at the mixing station, mixed, transported to the location used by the truck, into a dedicated storage container, and used in the specified time the finished wet mixture.

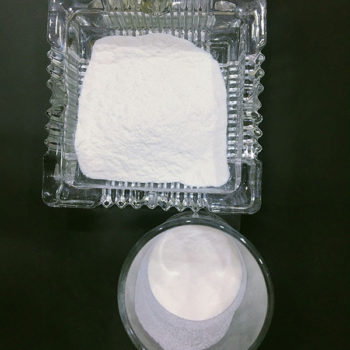

Hydroxypropyl methyl cellulose is used as water retaining agent for cement mortar, retarder mortar pumping. In gypsum as a binder to improve the application and extend the operation time, hydroxypropyl methylcellulose HPMC water retention so that the slurry after drying will not be too fast and crack, hardening to improve the strength. Water retention is an important property of hydroxypropyl methyl cellulose HPMC, and it is also the concern of many wet mortar manufacturers. The factors that affect the water retention effect of wet mortar include the amount of HPMC added, the viscosity of HPMC, the fineness of particles and the temperature of the using environment.

Hydroxypropyl methyl cellulose HPMC in wet mortar main role in three aspects,

one is excellent water holding capacity, the second is the wet mortar consistency and thixotropy of the influence, the third is the interaction with cement. Cellulose ether water retention depends on the water absorption rate of the base, mortar mortar composition, mortar layer thickness, mortar water demand, setting time. The higher the transparency of hydroxypropyl methyl cellulose, the better the water retention.

The factors affecting water retention of wet mortar include the viscosity of cellulose ether, adding amount, particle size and temperature. The greater the viscosity of cellulose ether, the better the water retention. Viscosity is an important parameter for HPMC performance. For the same product, using different methods to measure the viscosity of the results vary widely, some even by a factor of two. Therefore, the viscosity comparison must be carried out in the same test method, including temperature, rotor, etc.

Generally speaking, the higher the viscosity, the better the water retention. However, the higher the viscosity, the higher the molecular weight of HPMC, and the lower the solubility of HPMC, which has a negative impact on the strength and construction performance of mortar. The higher the viscosity, the more obvious the thickening effect of mortar, but it is not directly related. The higher the viscosity, the more sticky the wet mortar, good construction performance, viscous scraper performance and high adhesion to the substrate. However, the improvement of the structural strength of the wet mortar itself did not help. Both construction, the performance is not obvious anti – hanging performance. In contrast, some medium and low viscosity but modified hydroxypropyl methylcellulose has excellent performance in improving the structural strength of wet mortar.

The greater the amount of cellulose ether PMC wet mortar added, the better the water retention, the higher the viscosity, the better the water retention. Fineness is also an important performance index of hydroxypropyl methyl cellulose.

The fineness of hydroxypropyl methyl cellulose also has a certain influence on its water retention. Under normal circumstances, the same viscosity and different fineness of hydroxypropyl methyl cellulose, under the same amount of addition, the smaller the fineness of the water retention effect is better.

In wet mortar, the addition of cellulose ether HPMC is very low, but it can significantly improve the construction performance of wet mortar, is the main additive that mainly affects the performance of mortar. The performance of wet mortar is greatly influenced by the reasonable selection of hydroxypropyl methyl cellulose