1. The basic nature of HPMC

Hydroxypropyl methylcellulose, English name hydroxypropyl methylcellulose, alias HPMC. Its molecular formula is C8H15O8-(C10Hl8O6) N-C8HL5O8, the molecular weight is about 86000. This product is a semi-synthetic material, which is part methyl and part polyhydroxypropyl ether of cellulose. Two methods can be used to manufacture: one is the appropriate grade of methyl cellulose after NaOH treatment, and then under high temperature and high pressure reaction with propylene oxide, the reaction time must be sustained to allow methyl and hydroxypropyl groups in the form of ether bonds to the cellulose dehydrated glucose ring, and can reach the desired degree; The other is to use caustic soda treatment of cotton wool or wood pulp fiber, methane chloride and propylene oxide has been obtained with its reaction, after further refining, grinding, so that it becomes a fine uniform powder or particles. HPMC is a variety of natural plant cellulose, is also an excellent pharmaceutical excipients, it has a wide range of sources. At present, it is widely used at home and abroad, and it is one of the pharmaceutical excipients with the highest utilization rate in oral drugs.

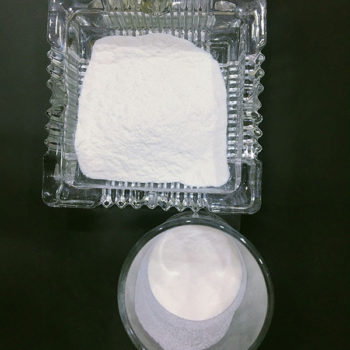

This product is white to milky white in color, non-toxic and tasteless, in the form of granular or fibrous and easy to flow powder. It is relatively stable under light irradiation and humidity. It expands in cold water to form milky colloidal solution, there is a certain degree of viscosity, sol-gel tautometry phenomenon due to a certain concentration of the solution of the temperature changes. Highly soluble in 70% alcohol or dimethyl ketone, but not in anhydrous alcohol, trichloromethane or ethoxy ethane.

Hydroxypropyl methylcellulose pH between 4.0~8.0, has good stability, pH between 3.0~11.0 can be stable, temperature at 20℃, the relative humidity of 80% under the state of storage for 10 days, HPMC moisture absorption coefficient is 6.2%.

Hydroxypropyl methylcellulose due to methoxy and hydroxypropyl, the two substituents in the structure of the different content, there are a variety of models of products, in a specific concentration, a variety of models of products with specific viscosity and thermal gelation temperature, so it has different properties, can get different uses. Each country’s pharmacopoeia has different type requirements and expressions: European pharmacopoeia according to sell products on the market of various levels of different viscosity, different degree of substitution, use level and Numbers, the unit is mPa s in the United States pharmacopoeia, common name followed by four digits to represent the hydroxypropyl methyl cellulose content of different substituent and model, for example, hydroxypropyl methylcellulose, 2208, the first two digits represent methoxy probably percentage rate, The last two numbers represent the approximate percentage of hydroxypropyl.

2.HPMC dissolved in water method

2.1 method of hot water

Since hydroxypropyl cellulose does not dissolve in hot water, it can initially be evenly dispersed in hot water, and then when cooled, two typical methods are described as follows:

(1) Put the required amount of hot water into the container, and heat it to about 70℃. Gradually add the product under slow stirring. At the beginning, the product floats on the surface of the water, and then gradually forms a slurry.

(2) in the container to add the required amount of 1/3 or 2/3 of the water, and heated to 70℃, so that the product dispersion, preparation of hot water slurry, and then add the remaining amount of cold water or ice water to the hot water slurry, stirring after cooling the mixture.

2.2 Powder mixing method

The powder particles are thoroughly dispersed by dry mixing with equal or greater quantities of other powdery ingredients, and then dissolved with water, where HMCS is dissolved without condensation.

3. The advantages of HPMC

3.1 Cold water soluble

It can be dissolved in cold water or 70% ethanol below 40℃, and it is basically insoluble in hot water above 60℃, but it can be gelated.

3.2 Chemical inertness

HPMC is a kind of non-ionic cellulose ether, its solution does not have ionic charge and does not interact with metal salts or ionic organic compounds, so in the process of preparation production, other excipients do not react with it.

3.3 stability

It is stable to acid and base, and can be stored between pH3 ~ 1l for a long time, and its viscosity has no obvious change. The aqueous solution of hydroxypropyl methylcellulose (HPMC) has anti-mildew effect and can maintain good viscosity stability during long-term storage. The quality stability of HPMC is better than that of traditional excipients (such as dextrin, starch, etc.).

3.4 The viscosity is adjustable

Different viscosity derivatives of HPMC can be in accordance with different proportions, its viscosity can be changed according to certain laws, and has a good linear relationship, so you can choose the ratio according to demand.

3.5 Metabolic inertness

HPMC is not absorbed or metabolized in the body and does not provide heat, so it is a safe excipient for medicinal preparations.

3.6 security

HPMC is generally considered to be a non-toxic and non-irritating material, with a median lethal dose of 5g /kg in mice and 5.2g/kg in rats. Daily doses are not harmful to humans.

4. Application of HPMC in preparation

4.1 Film coating material and film forming material

Hydroxypropyl methylcellulose (HPMC) is used as the film coating material, the coated tablets have no obvious advantages over the traditional coating tablets such as sugar coated tablets in masking drug taste, appearance and other properties, but its hardness, fragility, moisture absorption, disintegration, coating weight gain and other quality indicators are better. The LOW VISCOSITY GRADE OF THIS product IS USED AS WATER-SOLUBLE FILM coating MATERIAL FOR tablets and pills, THE HIGH VISCOSITY grade is used AS FILM coating material for organic solvent system, the concentration is usually 2.0%~20%.

4.2 As a binder and disintegrant

The low viscosity level of this product can be used as a tablet, pill, granule binder and disintegrant, high viscosity level can only be used as a binder. The dosage varies according to the model and requirements, generally 5% for dry granulation tablets and 2% for wet granulation tablets.

4.3 As suspension aid

Suspension aid is a kind of viscous gel substance, with hydrophilic, in suspension aid can be used to slow down the settling speed of particles, and it can be attached to the surface of particles, to stop the particle polymerization into a ball. Suspension aid plays an important role in the production of suspension agent. HPMC is an excellent variety of suspension aid, its dissolved colloidal solution can reduce the tension of liquid-solid interface and the free energy of small solid particles, and then enhance the stability of heterogeneous dispersion system. The high viscosity level of this product as suspension preparation of suspension liquid preparation, suspension effect is good, easy to disperse, non-sticky wall, fine flocculating particles, its usual dosage of 0.5% ~ 1.5%.

4.4 As a blocker, slow and controlled release agent and pore agent

The high viscosity level of this product is used to prepare hydrophilic gel skeleton sustained release tablets, mixed material skeleton sustained release tablets of blocker and controlled release agent, has the effect of delaying drug release, its use concentration is 10%-80% (W/W). Low viscosity levels are used as pore-inducing agents in sustained-release or controlled-release formulations. The initial dose required for the therapeutic effect of such tablets can be rapidly reached, followed by a sustained-release or controlled-release effect, and effective blood concentrations are maintained in vivo. Hydropropyl methylcellulose is hydrated in water to form a gel layer. The release mechanism of drugs from the skeleton tablet mainly includes the diffusion of the gel layer and the dissolution of the gel layer.

4.5 Protective glue for thickening agent and colloid

When this product is used as thickening agent, the common concentration is 0.45%~1.0%. This PRODUCT can also increase the stability of hydrophobic glue, the formation of protective COLloid, prevent particle COALescence, condensation, thus inhibiting the formation of sedimentation, its commonly used concentration of 0.5%~1.5%.

4.6 Used as capsule material

Usually capsule capsule shell capsule material to gelatin. The production process of Ming capsule shell is simple, but there are some problems and phenomena such as poor protection against wet and oxygen sensitive drugs, reduced drug dissolution and delayed disintegration of capsule shell during storage. So hydroxypropyl methylcellulose as a substitute for Ming capsule material used in the preparation of capsule, improve the capsule manufacturing molding and use effect, has been widely promoted at home and abroad.

4.7 As a bioadhesive

Biological adhesion technology, the application of excipients with biological adhesion polymer, through adhesion to the biological mucosa, enhance the consistency and tightness of the contact between the preparation and the mucosa, so that the drug is slowly released, and absorbed by the mucosa, to achieve the purpose of treatment, currently widely used in the treatment of nasal cavity, oral mucosa and other parts of the disease. Gastrointestinal biological adhesion technology, is a new kind of drug delivery system developed in recent years, it not only makes the residence time to extend the pharmaceutical preparations in the gastrointestinal tract, and make the contact of drugs and cell membrane absorption parts performance improvement, change the cell membrane fluidity, that the penetration of drugs on small intestinal epithelial cells, so as to improve the bioavailability of drugs.

4.8 As a topical gel

As a kind of skin adhesive preparation, gel agent has a series of advantages, such as safety, beautiful, easy to clean, low cost, simple preparation process, good drug compatibility and so on. In recent years, gel agent has been widely concerned and become the development direction of skin topical preparation.

4.9 As precipitation inhibitor of emulsification system

5. The production of HPMC

Calocan’s hydroxypropyl cellulose, sold under the brand name Methocel, comes in three series — E, F and K — with a variety of models available for each. E series are mainly used as film coating material for tablet coating and sealing tablet core: E and F series are used as adhesives and release inhibitors for eye preparations, suspension and thickening agents for liquid preparations, adhesives for tablets and granules; K series are mainly used as release inhibitors and hydrophilic gel skeleton materials for slow and controlled release preparations.